As critical resources grow scarce and regulations tighten, traditional engineering approaches fall behind. Our Industrial AI platform enhances your existing processes and infrastructure — designing smarter process variants, material combinations, and production configurations before you commit to costly physical changes.

40X FASTER INNOVATION

Dramatically shorten development cycles.

25% COST REDUCTION

Streamline operations, reduce waste, and boost efficiency.

ADAPTIVE PROCESSES FOR BETTER QUALITY

Maintain consistent output despite fluctuating inputs and constraints.

€50K INVESTMENT → €MILLIONS OF SAVINGS

Unlock measurable business value within 12 months.

Our Industrial AI Platform offers two powerful, ready-to-deploy solutions designed to tackle process complexity and accelerate product innovation:

Paper Manufacturer: €1.2M+ in annual energysavings through intelligent process control

Chemical Company: 15% increase in plantefficiency despite constantly changing recycling fractions

Recycling Company: €5M in savings throughvirtual plant ramp-up

Cement Manufacturer: New formulation with 80%less CO₂ — developed in just 8 weeks

Packaging Producer: Food-safe packaging with30% recycled content — developed in just 6 weeks

Polymer Manufacturer: 85% fewer experiments todevelop new formulations

With iteratec's AI-driven approach, we simulate thousands of solution paths while considering factors like expected performance, costs, and sustainability early on. This enables us to identify highly complex solutions that would be unreachable with conventional research.

Leading Chemical Company

We work closely with international organizations, research institutions, and open-source initiatives to drive sustainable innovation in industry.

![[Translate to en:] Logo United Nations Industrial Development Organization](/fileadmin/_processed_/9/9/csm_itertec_sustainable-Solutions_Partner_2_14f12acdb6.png)

![[Translate to en:] Logo Global Alliance on AI for Industry and Mannufacturing](/fileadmin/_processed_/c/4/csm_itertec_sustainable-Solutions_Partner-1b_eb0d63cb0b.png)

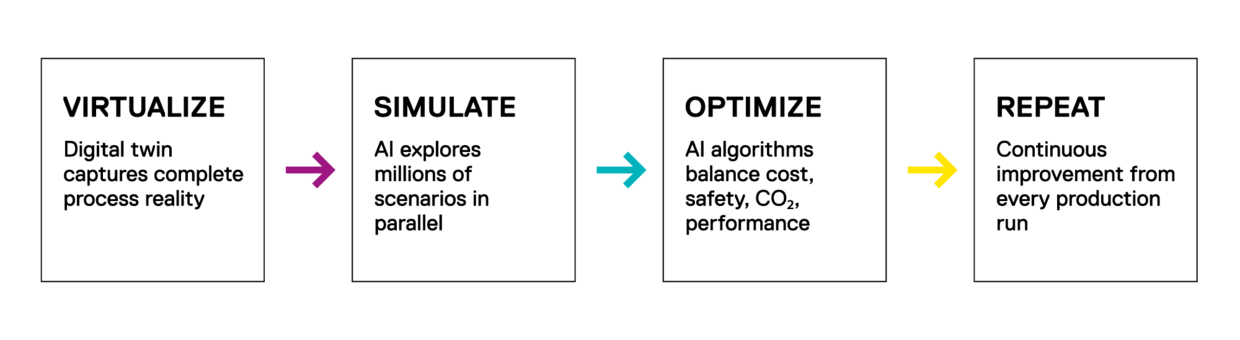

Forget costly CAPEX projects and multi-year rollouts with uncertain outcomes. Our AI-first approach embraces variability as the new normal – learning from your data, adapting in real time, and getting better with every cycle. The result? Smarter decisions, faster value creation, and systems that remain resilient – even as conditions change.

No new sensors or hardware required

Seamlessly integrates with your existing SCADA/ERP systems

Operable by lab and process teams – no AI expertise needed

Fully traceable outputs – ready for regulated environments

Traditional AI approaches quickly reach their limits in industry. Our Industrial AI Playbook shows how companies can create real added value in just a few weeks with a decision-focused, adaptive approach – instead of spending years collecting data. Learn how the four fundamental shifts make the difference and how you can achieve measurable results quickly with AI-first strategies.

Review your biggest challenges. Identify highest-impact AI opportunities with our experts.

Technical validation in your real environment. Measure effectiveness and build confidence.

Production-ready system, then step-by-step expansion to other processes.